A system designed to support the entire journey of injectable therapies in hospital pharmacies — from prescription to logistics, compounding, and administration.

Developed over 20 years through continuous collaboration with designers, engineers, and healthcare professionals from 200+ leading institutions around the world.

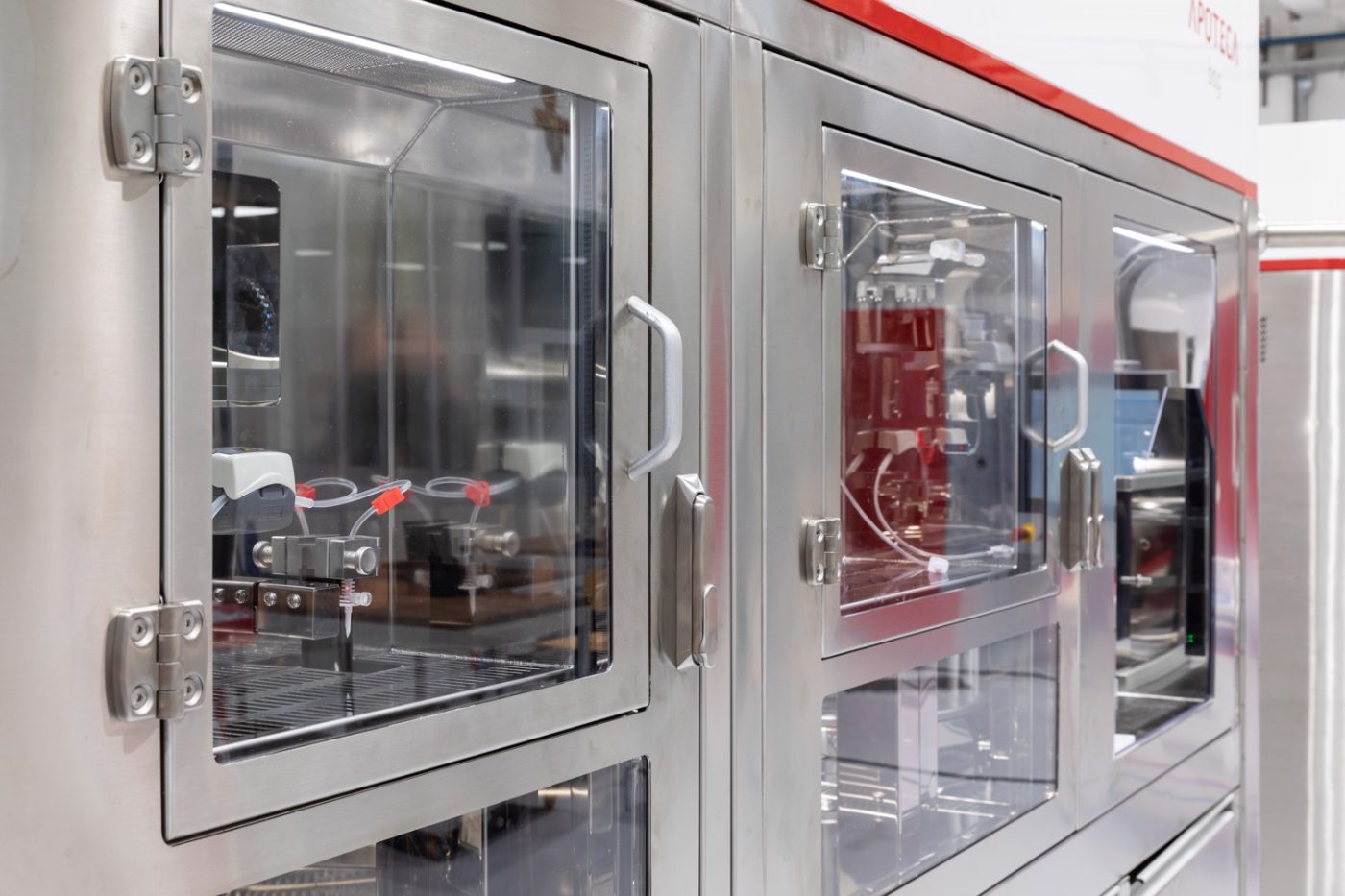

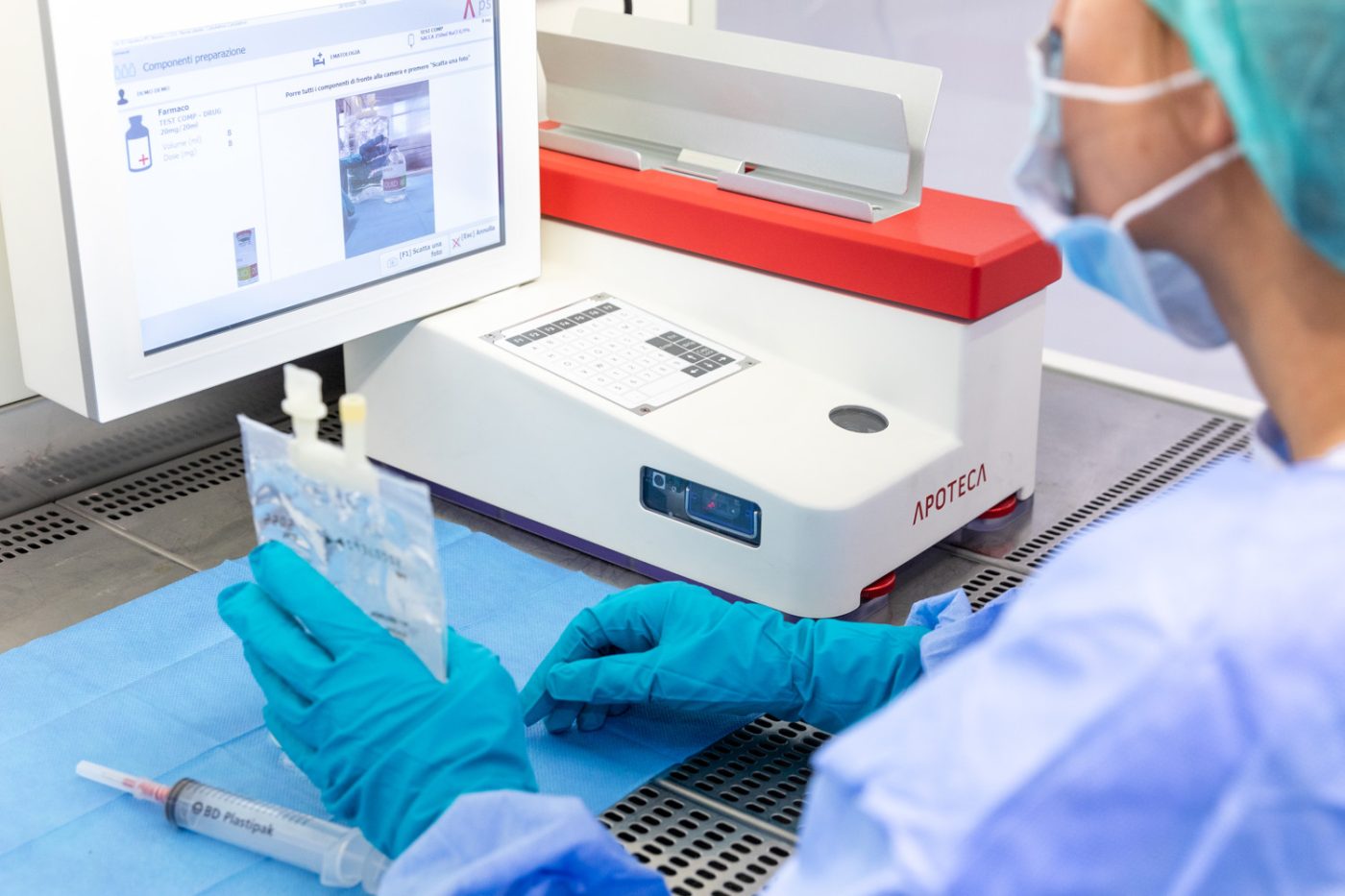

It brings together software, sensors, and robotics into a single, integrated workflow. The software is the mind: it sees, decides, and coordinates. The sensors are the senses: they observe, measure, and report. The robots are the hands: they prepare, move, and deliver.

Every action is traced, every step is controlled, every dose is accounted for — so that care reaches each patient safely, precisely, and without waste.

The Apoteca platform

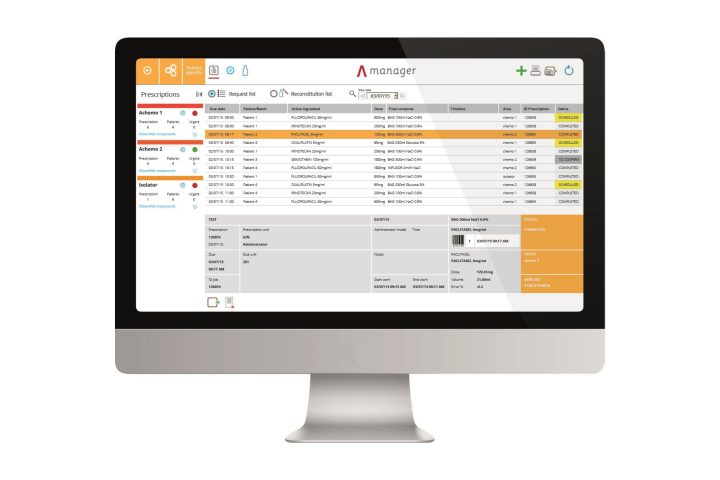

Software solution designed to smartly manage pharmaceutical production, whether in a single hospital or across a complex health system. It interconnects all APOTECA compounding systems, is bidirectionally integrated with the electronic health record, and incorporates artificial intelligence to enhance efficiency and productivity.

Robotic system for compounding of personalized oncology therapies in IV bags, syringes, and continuous infusion pumps. Operating under negative pressure within an aseptic environment, it ensures absolute safety, traceability and accuracy through independent control and measurement systems that certify the quality of the compounded therapies.

Software solution for the management of clinical trials, both oral and IV, including the management of protocols, inventory, accounting, compounding process control, digital documentation, and standardized, and automatic reporting.

Robotic system for the batch compounding of non-hazardous therapies in syringes. Thanks to the standardization of the process, it achieves a productivity up to ten times higher than that of personalized therapies. The system is fully automated and delivers a labeled and tamper-evident sealed product, ready for administration without any further handling.

Robotic system for the batch compounding of non-hazardous therapies in IV bags or of multidose bulk bags, starting from drug vials (liquid or powder). The system is fully automated and delivers certified ready-to-administer products.

Robotic system for the compounding of non-hazardous therapies into IV bags, syringes, and continuous infusion pumps. Operating under positive pressure, it supports both batch production and patient-specific preparations. Fully automated, the system delivers certified ready-to-administer products.

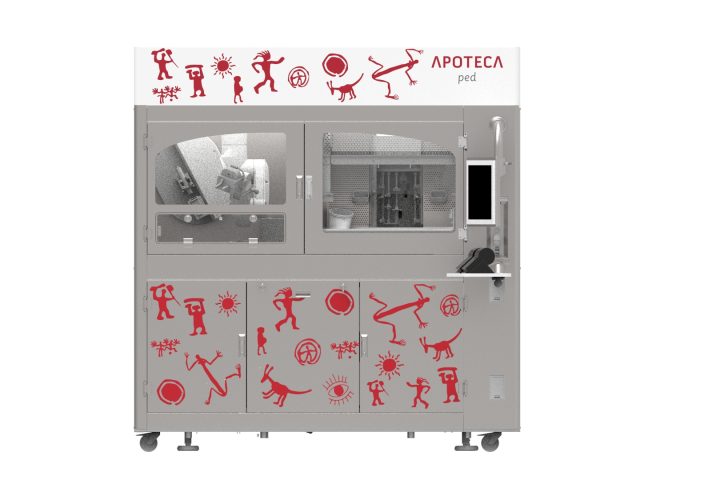

Robotic system for compounding of personalized non-hazardous pediatric therapies into IV bags, syringes, and continuous infusion pumps. Operating under positive pressure within an ISO Class 5 environment, it ensures absolute safety, traceability and dosing accuracy for small volumes using the 1 ml syringe.